If I remember correctly, I found both of these TP&W boxcars at train shows while I was in college. They are Athearn Blue Box cars custom-decorated by Bev-Bel. In addition to different car numbers, there are also subtle differences in the lettering.

More recently, Athearn and Accurail have both offered models of these cars, but to my eye these newer cars are painted a shade of orange that is too light. The darker orange on the Bev-Bel cars looks more like the few prototype photos I have seen (examples

here and

here). These two cars were my worst performers on the Illini Railroad Club layout. They had a tendency to come uncoupled from other cars, especially on grades. This performance was likely a consequence of chronically low coupler height, as shown below. I didn't try to fix them back then; they simply got banished from the club layout.

I had one of these cars in the inaugural train on my new layout, and even with no grades, it still came uncoupled from the rest of the train. It's time to fix these cars so I can run them.

The Easy Way

Probably the most common way to fix low coupler height is to use washers above the trucks to raise the carbody relative to the wheels. I went this route for TP&W 70157.

Prior to installing the washers, I addressed some other low-hanging fruit. Part of the low-coupler problem was that the tops of the coupler boxes weren't sitting flush with the bottom of the weight like they're supposed to be. There were two reasons for this: casting flash on both the car floor and underframe pieces and a bowed weight. These are things that I always check for now when assembling car kits, but I wasn't always so careful in the past.

|

| There were small raised projections and bits of flash on the plastic floor piece that prevented the steel weight from sitting flush with the bottom of the floor. I removed these with a #17 chisel blade. |

|

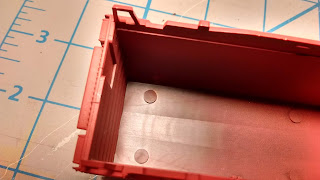

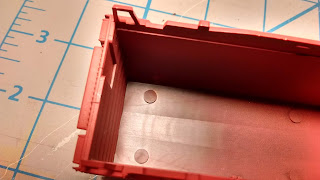

| There were also bits of flash on the top of the underframe piece where you see the small circular indentations on the photo above. I removed these with a #11 blade and filed them smooth with a flat needle file. |

|

| As shown above, the steel weight has a curve to it. Because the weight gets sandwiched between the underframe and the floor, the plastic underframe and floor will flex to conform to the shape of the weight. If the weight is bowed and/or twisted badly enough, then the trucks won't sit square to the rails and the car will track poorly. |

|

| I carefully flattened the weight by bending it with my fingers, and also checked to make sure it wasn't twisted. |

|

| I added a red (0.015") Kadee washer to each truck bolster as shown above, then reinstalled the trucks. I also replaced the original plastic wheels with Walthers metal ones. The Walthers axles seem slightly too short for the Athearn truck frames; I may have to either replace the trucks or use different wheelsets later if the current configuration causes problems. |

|

| The finished car compared to the Kadee coupler height gauge. The coupler is very slightly low, but much better than before. |

The Hard(er) Way

While the washer method was successful at raising the coupler height, the couplers also don't stick out far enough from the end of the car. For car #70138, I decided to modify the underframe to both fix the coupler height without using washers and move the couplers out farther from the car end.

Because the tops of the stock coupler boxes are flush against the weight, raising the coupler boxes would require notching the steel weight. To avoid doing that, I instead decided to install the weight on top of the floor and fill the cavity between the floor and the underframe with styrene. The weight is 0.055" thick, so it can be replaced with pieces of 0.015" and 0.040" Evergreen styrene laminated together. The coupler height needs to be raised approximately 0.015", so I can cut notches in this piece for the coupler boxes.

|

| Here's the floor with pieces of styrene cut to replace the weight. Using the weight as a guide, I drilled two 7/32" holes to clear the bosses for the truck screws. |

|

| I bought these Walthers cushion coupler pockets because these cars say "Cushion Service" on their sides. However, prototype photos of the TP&W cars don't show the couplers sticking out quite as far as the picture on the Walthers package. I will still use the Walthers parts to replace the original Athearn coupler boxes but won't follow the Walthers mounting instructions. |

|

| Here's what the Walthers coupler boxes look like. The "tongs" are supposed to fit in the stock coupler box so that the new box projects out from the end of the car. |

|

| The Walthers lids are intended to be glued onto the box, but I want them to be removable for maintenance. I drilled out the boss on the box with a #50 drill and made a hole in the lid with a #43 drill. |

|

| With the underframe in place, I marked the sides and ends of the Athearn coupler boxes with a pencil. |

|

| Next, I used the pencil marks as a guide to cut a notch in the 0.015" styrene. Then I cemented the piece of 0.040" styrene to the black plastic floor and cemented the 0.015" piece on top of it. |

|

| I sawed off the Athearn coupler box from the underframe as shown. The end of modified underframe lines up with the notch. Mounting the Walthers box in this notch puts the coupler end of the Walthers box about even with the platform on the end of the car, which was right where I wanted it. |

|

| I cut the "tongs" off the back of the Walthers box and shortened the lid to match. Then I cemented the Walthers box in the notch in the styrene as shown. I also had to notch the end of the black plastic floor slightly to clear the new raised box. |

|

| Here's the completed underframe with both new coupler boxes in place. |

|

| At this point I mounted the trucks and checked the coupler height. Looking good. |

|

| I used double-sided tape to attach the weight to the top of the floor. |

|

| After painting the white styrene and brown coupler boxes black, it was time to install the modified floor/underbody assembly into the car body. I also had to notch the ends of the body to clear the raised coupler boxes. I test-fit the floor into the body and marked the location of the coupler box with a knife as shown above. |

|

| I notched the body about even with the middle of the row of molded-on bolts. |

|

| Here's the finished product. Coupler height is spot-on, and the coupler now sticks out farther from the end so the cars won't couple too close together. |

I like how the 70138 turned out, so I will probably go back later and do the same thing to #70157.