This is an older Accurail kit that has friction-fit coupler box covers and uses plastic friction pins to secure the trucks. I prefer screw-mounted couplers and trucks for ease of adjustment and maintenance, so I will retrofit this car with screws. I recently decided to require metal wheels on all cars on the layout, so the stock plastic wheels on this car need to be replaced. The Accumate coupler has been my standard since 1998; I'm not exactly sure why this car is equipped with Bachmann E-Z Mate couplers, but those will need to get replaced with Accumates as well. I suspect that this car was too old to come factory-equipped with Accumates, and I must have just used whatever I had handy when I assembled it.

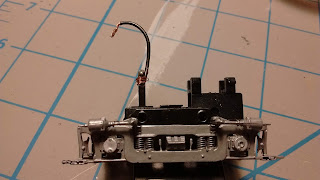

First, I carefully removed the car floor. The trucks and couplers are both mounted directly to the floor, and the tops of the friction pins are visible from the top of the floor.

This nail set is just the right size to push the friction pins out from the top side of the floor.

I removed the truck pins first. This was a two-hand job so I couldn't photograph it, but I held the car by the truck bolster in my left hand and then used my right hand to push firmly on the pin with the nail set. Once the truck pins were out, then I repeated the process for the coupler box covers, this time holding the car in my left hand as close to the coupler box as possible.

|

| They're out. |

I replaced the stock plastic 33" wheels with Walthers metal 36" wheels, and then mounted the trucks with the same screws. Having screw-mounted trucks allows me to give the car a "three-point suspension" - tighten one truck so that it can only swivel and leave the other a bit looser so it can swivel and also rock slightly.

After reassembling the car, I checked the coupler height. With the stock 33" wheels, the coupler height was a bit low compared to the Kadee height gauge. With the replacement 36" wheels, now the coupler height is just right.

|

| Before: Low coupler with 33" wheels |

|

| After: Spot-on coupler height with 36" wheels |